Spray dispensing valve as the core accessories of dispensing equipment, mainly uses low viscosity fluid to spray. In order to protect the surface of the product, it will spray a protective film for dust prevention, wear prevention and moistureproof. It is commonly used in the electronics industry. The circuit board needs three anti paint spraying, and some use the ink industry will use this spray dispensing valve to be a high frequency spray valve.

There are two types of high frequency spray valve, which are divided into two types: round and fan-shaped. The two difference is that the spray angle and range are different, the circle is relatively concentrated, the adjustment angle is 45 degrees, and the fan angle is 137 degrees, the scope is different, the fan angle is bigger, and the uniformity is not round high, because the circle is a center, the circular way spreads from the four sides, the evenness is excellent. Breadth or fan-shaped high frequency spray valve is excellent.

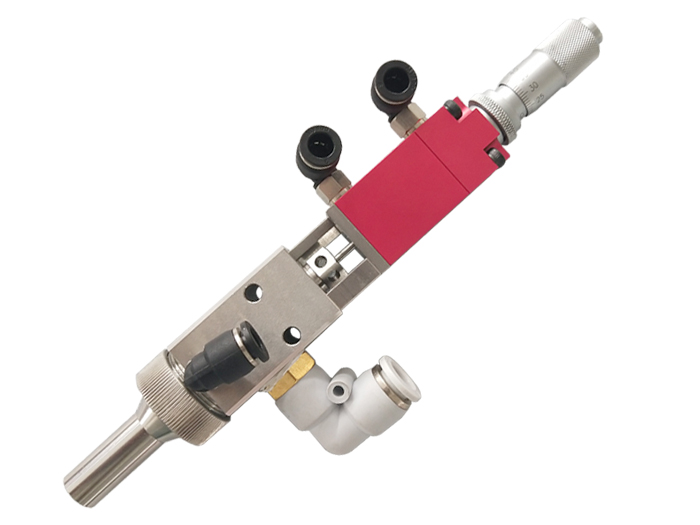

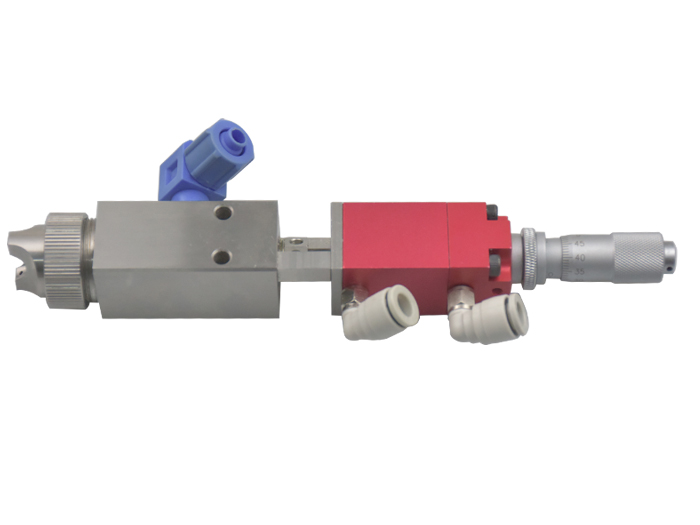

High frequency spray valve real map

High frequency spray valve parameters

Model: zz-65s

Working air pressure: 4 ~ 7kgf / cm

Form: suction back

Operating frequency: < 400 / min

Main material: stainless steel + aluminum alloy

Overall length: 203 * 21 * 21 (length, width, height)

Operating viscosity: 1 ~ 5000cps

Spray effect: foggy

Usage: with dispensing machine or manual spraying

Characteristics of high frequency spray valves

1, detachable spray head, multiple process structure, in spray nozzle for conditioning, spraying wider.

2, uniform spray, no water droplet formation, easy cleaning, avoid clogging.

3. Metal spray spray valve is made of stainless steel with good anticorrosion.

4. Use micrometer to make micro adjustment. The accuracy of micrometer is obvious to all. The accuracy can be adjusted as 0.01mm.

5. It can realize high-precision operation, with precision in margin adjustment and easy to control distance.

Application of high frequency spray valve

1, paint

2, alcohol

3, liquid

4, grease

5. White emulsion