Today, I'd like to share with you the types and characteristics of seven types of dispensing valves that we have made, what are their characteristics and what types of glue can be used.

1. spray valve

Spray valves are most suitable for low viscosity glue, especially for glue with viscosity less than 1500cps. The viscosity of water is 1 CPS, while that of mustard is about 200000 CPS. To select an appropriate spray valve, we need to give full consideration to the spray direction and the central controller of the dispensing valve itself. The central controller ensures that the glue is atomized before spraying, and after spraying, it can quickly repair the original situation, so as to avoid the glue blocking in the valve. Spray valves are mainly used to spray paint and glue.

Spray dispensing valve

Because of its strong operability for liquid, needle valve is very suitable for all kinds of single and two-component glue, and is mostly used for small-scale glue mixing. This kind of dispensing valve is generally adjustable, which can actually operate high viscosity non filling glue under high pressure. Because the actual operation time of needle valve is uncertain, it can also be used to draw line and adjust glue with low to medium viscosity glue. The needle valve has a valve needle installed in the middle of the wet chamber and the movable content component. The valve needle can be disassembled and replaced, so that the maintenance plan can be made according to the operation frequency of the needle valve. Needle valve is not suitable for grinding glue to prevent blocking the safety channel in the valve.

3. diaphragm valve

Diaphragm valve is used for adjustable and high frequency glue adjustment. It is suitable for many glue with low and medium viscosity, such as glue, fluid and grinding raw materials. Diaphragm valve is light and easy to maintain.

The short pipe valve is suitable for high viscosity paste, syrup and gel glue. In order to transport high viscosity glue, the spool valve must be operated under high pressure. This kind of dispensing valve has the function of suction back. Spool valves are also suitable for line drawing. Under the special intelligent control, the spool valve can draw lines and apply glue along the movement track of the sealing ring.

Special double liquid dispensing valve

5. raising valve

The lift valve is similar to the short pipe valve, for example, it often has the function of suction back. However, the valve is suitable for low and medium viscosity glue, and the glue output is smaller than that of the short pipe valve.

6. pinch valve

Because of its throwing wettable components, the pinch valve is very suitable for water-soluble resin adhesive glue. Under the control of clamping pipe, the dispensing valve can carry out the actual operation of medium level precision and repeated dispensing. The pipe clamping valve is generally used for mixing two components of glue and instant dry raw materials. During the specified period of time, the replacement of the clamp pipe must be carried out, but it is low cost.

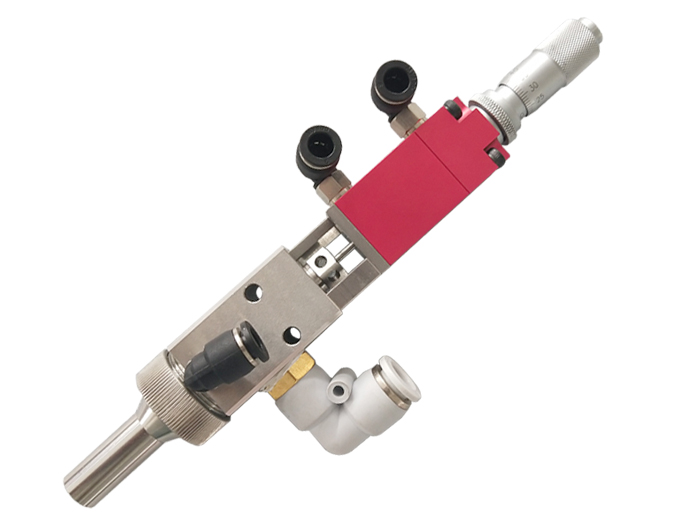

Plunger dispensing valve

The volume valve is used for the actual operation of high precision and small amount of dispensing. The volume valve is divided into two categories: air control valve and motor control valve. Motor control valve is also called screw valve. Select one of the two categories according to the viscosity of the glue and the specified delivery amount