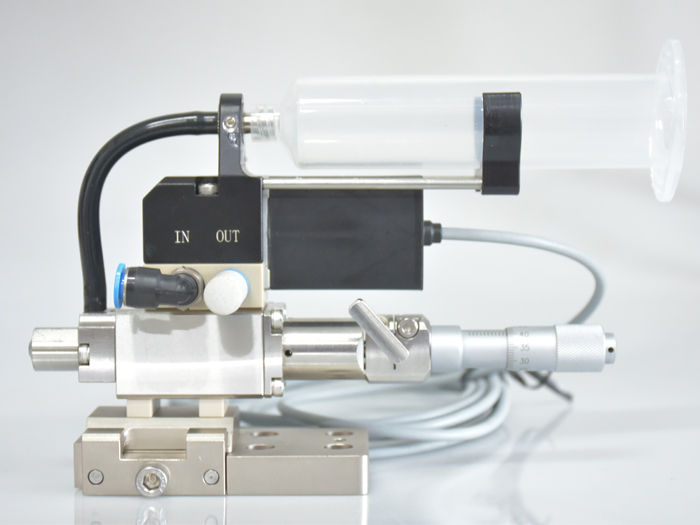

The piezoelectric injection valve adopts the electric mode, uses 24V AC to control the glue flow, and realizes the glue injection in the high-pressure state. The glue spraying frequency can reach 500Hz / s, the working efficiency is super high, and collision with the product can be avoided. The needle can not be used, and the existing high-precision dispensing can still be realized, and the air pressure is not connected.

According to the type of glue used

It is suitable for dispensing requirements of various types of glue, including silica gel, epoxy resin glue, red glue, black glue, crystal glue, paint, ink, etc. the viscosity requirement is below 30000, the dispensing effect of higher viscosity is still satisfied, the spraying frequency is slower, less than the highest frequency, the water flow of glue has a certain impact on the spraying, and the effect of spraying paint can be reflected in the most case, because The paint has good fluidity, and the precision glue spraying valve has good sealing, so it is especially suitable for spraying with low viscosity glue.

Optional matching

On the piezoelectric spray valve, in order to meet more glue application requirements, heating device can be selected. Some glues need to be heated before dispensing. For example, hot melt glue and red glue are heated at the needle tip, which is conducive to improving the fluidity of glue, and the continuity of spray glue is also improved, which is conducive to production. The heating device is an optional accessory, and the corresponding device can be selected according to the requirements.

The high glue spraying technology is mainly due to the good combination effect of accessories. The aperture of glue dispensing needle can reach 0.075mm precision, which is a very small glue dispensing effect. There are other types of needles, which are prepared to meet the glue dispensing requirements of various industries, and can also be selected according to the viscosity requirements. All accessories are designed to meet the accurate glue dispensing production. The same is true for the research and development of glue spraying technology. In fact, piezoelectric technology is used The effect of the spray valve is very uniform, and it is convenient to clean and maintain.