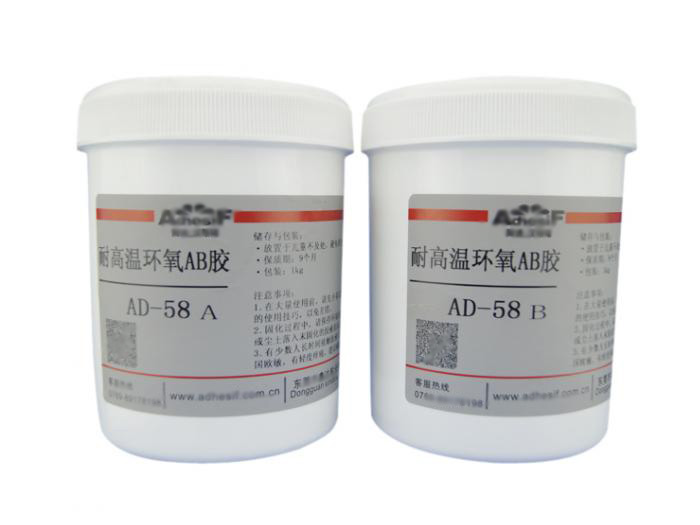

There are many difficulties in double liquid glue filling. There is no contrast between single component glue and single component glue. After the two kinds of glue are mixed, there will be some changes in viscosity, fluidity, characteristics, etc., some of which may become low viscosity, some may increase viscosity, and it is necessary to know the mixing effect, so as to match the corresponding double liquid dispensing valve.

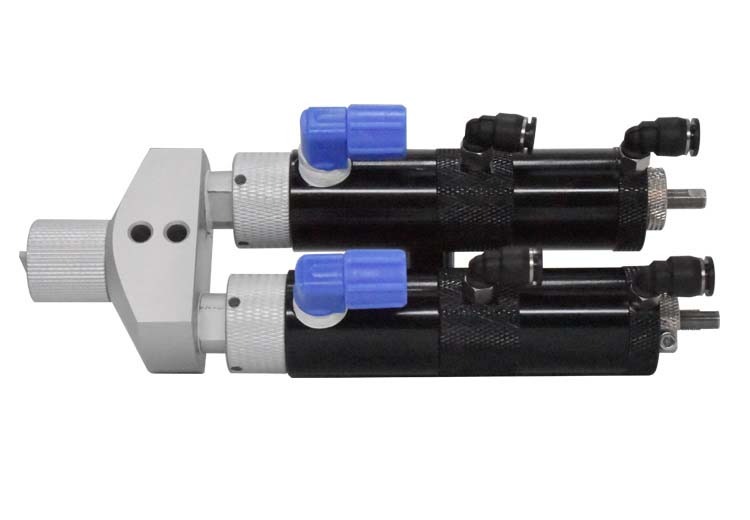

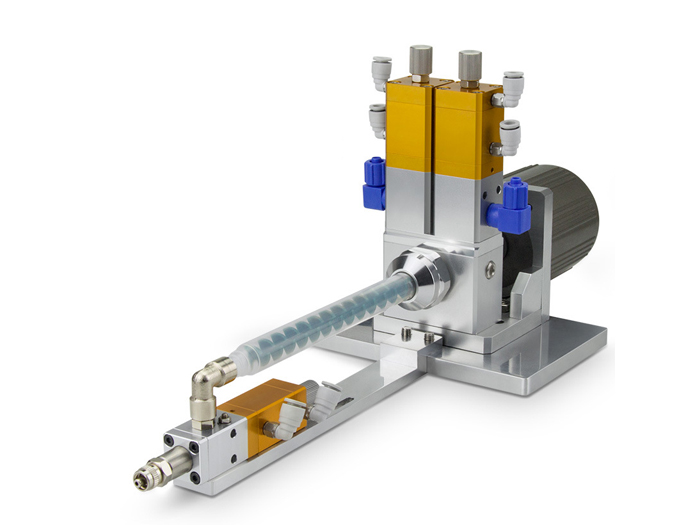

Mixing and dispensing valve needs glue mixing proportion, glue viscosity, glue filling requirements, etc., and then matching the corresponding equipment, it can really fill glue. Otherwise, it's all on paper. Some manufacturers will tell you directly how much the machine price is. In fact, the price given is not accurate, and they will definitely tell you with higher requirements, so that your company can meet the requirements of products, glue and speed Only when you are ready, can you get the most accurate price. Use double liquid glue to fill the glue. Some need static two-component dispensing valve, some need dynamic two-liquid dispensing valve. The price difference between the two is very large, almost several hundred pieces. Only when you determine the parameters, can you choose accessories, and the price is appropriate.

Difficulties of double liquid glue filling:

Difficulties of double liquid glue filling:

1. The difference of glue mixing ratio is too large to be achieved when the ratio is more than 10:1, for example, 20:3, which is a problem.

2. The viscosity of the glue is too high to meet the requirements. The viscosity of the glue reaches one million, which is basically unable to flow and dispensing.

3. There are particles in the glue. In order to strengthen the solidification effect of the glue, some manufacturers will add particles in the glue, which will also cause the two-component dispensing valve unable to bear the damage. Although the glue can be filled, the cost is very high. A dispensing valve can only be used for a few days, and can not be used again.

The above three points are the difficulties of double liquid glue filling at present. As long as these three points are involved, they can not be achieved basically. Although the double liquid dispensing valve is made of stainless steel materials, it belongs to high-precision products, and air leakage can not be used. That's why the glue with particles can not be used, which is easy to cause air pressure leakage.

Attention should be paid to the use of mixed dispensing valve. If the manufacturer has requirements, our company can also make corresponding equipment to see if it meets the requirements. Our company also makes automatic equipment, including dispensing machine, filling machine, dynamic double liquid dispensing valve, stainless steel pressure bucket and other accessories. As long as it is not the difficulty of double liquid glue filling, this method can be used!

Attention should be paid to the use of mixed dispensing valve. If the manufacturer has requirements, our company can also make corresponding equipment to see if it meets the requirements. Our company also makes automatic equipment, including dispensing machine, filling machine, dynamic double liquid dispensing valve, stainless steel pressure bucket and other accessories. As long as it is not the difficulty of double liquid glue filling, this method can be used!