The use of mixing dispensing valve is generally related to glue. Mixing means mixing two kinds of goods together. In glue industry, there is a kind of two-component glue, which needs to be mixed to achieve the solidification effect. According to the above situation, we can know that the mixing dispensing valve meets the use requirements of two-component glue water. This is the glue valve made by our company to solve the automatic mixing of two-component glue, but Some double liquid glues are very difficult to handle, so it is necessary to select machines and accessories specifically.

Difficulties of double liquid glue filling

Difficulties of double liquid glue filling

1. High glue mixing ratio, 5:1 and above, 10:1 and below, which requires special two-component dispensing valve to realize dispensing. For example, screw dispensing valve, which exceeds the above mixing ratio, currently has technical difficulties and cannot be mixed.

2. Glue viscosity is one of the reasons that affect glue mixing. Generally, 50000 starting glue is difficult to achieve dispensing. When two kinds of glue are mixed together, the glue viscosity will be higher. The double liquid dispensing valve is unable to mix glue at all, and the dynamic double liquid dispensing valve is still not able to use.

3. The application of glue filling is suitable. It is customized according to the production requirements of the industry. Many manufacturers can't do it. Generally, large machines are used for glue filling. Some small manufacturers can't produce it at all. They can only buy it from large manufacturers and then sell it.

3. The application of glue filling is suitable. It is customized according to the production requirements of the industry. Many manufacturers can't do it. Generally, large machines are used for glue filling. Some small manufacturers can't produce it at all. They can only buy it from large manufacturers and then sell it.

The above is the difficulty of double liquid glue filling. The first and the second are still difficulties in our country. The manufacturer can't do it for sure, which is also the direction of our company's research and development. At present, for glue with viscosity less than 100000, the above needs to be done according to the actual situation. Otherwise, I can't do it or not. Because glue is on the one hand, and product requirements are on the other hand. Only combining with the actual situation can we do it Observed.

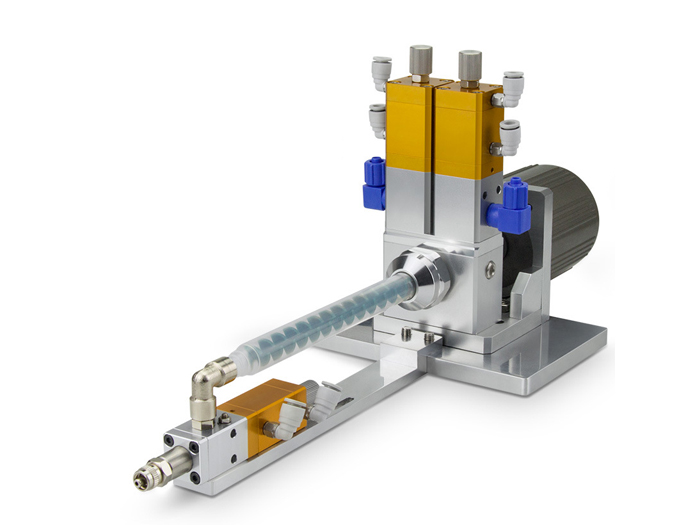

The two-component dispensing valve is also known as the two-liquid dispensing valve, and the glue valve is divided into static and dynamic two-liquid dispensing valves. The glue used in static state tends to be low viscosity and low proportion, while the dynamic two-liquid dispensing valve is the opposite. Because of the help of the motor, the glue mixing effect is improved, and the glue viscosity is higher, the glue mixing can be realized.

The two-component dispensing valve is also known as the two-liquid dispensing valve, and the glue valve is divided into static and dynamic two-liquid dispensing valves. The glue used in static state tends to be low viscosity and low proportion, while the dynamic two-liquid dispensing valve is the opposite. Because of the help of the motor, the glue mixing effect is improved, and the glue viscosity is higher, the glue mixing can be realized.

There are still some skills to use the mixing dispensing valve. Different from the ordinary dispensing valve, we need to pay attention to the type of glue, whether it has the mixing effect, whether the glue flow meets the requirements, whether the glue filling speed is fast enough, etc. all these need to be considered. The machine is different from the conventional products.