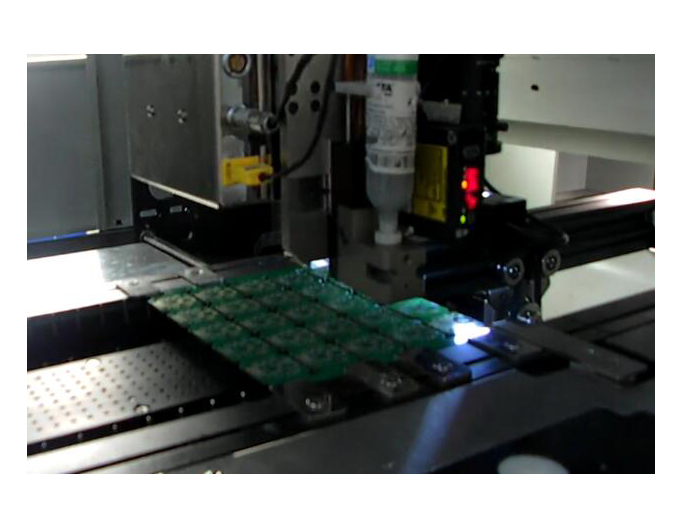

The emergence of automatic dispensing equipment improves the quality of the product's glue dispensing accuracy and so on. With high precision fixed-point glue control technology, glue can be completely filled and poured into the surface. It is suitable for controlling the use of the product in plane sealing or packaging. It can accurately control the taper needle dispensing glue on the product's surface by setting parameter paths. The taper needle does not scratch the product's surface at the same time. Enhanced the quality of product glue control, is used for smaller bulb lamp glue and filter glue and other needs of a kind of glue dispensing effect, which is inseparable from the performance and function of automatic glue dispensing equipment.

Strengthening the technical application of dispensing machine-controlled glue

The automatic dispensing machine can connect the control board of the controller to set parameters to achieve the effect of fixed-point glue control, including path parameters and simple program setting of dispensing. The connecting control board will need to set the route of dispensing glue at fixed point. After setting default parameters, it will gradually adjust the operating parameters such as pressure, speed and so on, which conform to the glue-filling process. It is suitable for bulb lamps with smaller structure. In the batch production lines of glue filling and filter gluing, the tapered needle assembled with PP material has been used for a long time without scratching the surface of the product and ensured the stability of efficiency, so as to improve the quality and quality effect of the fixed-point glue control of the product, and has become an automation equipment commonly used in plane sealing.

Polychromatic PP Conical Needle

Compared with manual dispensing machine, automatic dispensing machine has the characteristics of saving labor efficiency, high quality and so on. The quality of automatic fixed-point control gum is much better than manual operation. There are obvious deviations in manual plane sealing of product surface and the operation efficiency is low. It is not suitable to use in plane sealing between products with large demand. It is only by stably controlling the dispensing position of machine and tapered needle that the automatic dispensing machine can be used in plane sealing between products with large demand. It can be used to complete the production line of spherical bulb glue filling and filter glue coating for precision requirement. The intervention of fixed-point glue control technology will provide a basis for the joint enhancement of efficiency and quality. It has become an application technology in the manufacturing of spherical bulb glue filling and filter glue coating with high precision and output requirements, and plays an important role.

Bulb Lamp Round Location Rubber Machine