When spraying air filter with dispensing machine, it is usually sprayed with foam gum. Sometimes it can be used as sealant for spraying. Precision dispensing valves assembled by automatic dispensing machine and tapered needles are also suitable for bonding with filters. They can be used in many production lines such as plane sealant coating, which can effectively improve the quality of air filter. Except for filters, they have the characteristics of automation, high precision and so on. Besides the prominent role of glue coating, it can also be applied to batch packaging of electronic products or glue filling of bulb lamps.

Necessity of gluing filters

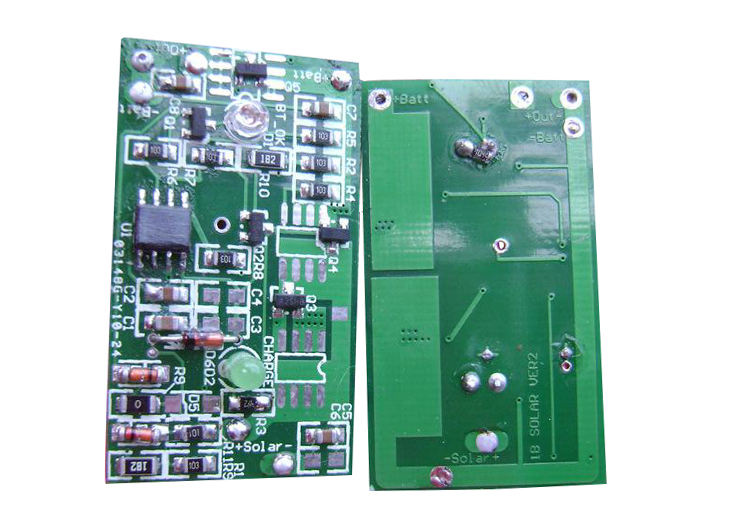

The bonding and fixing of the filter place on the machine should be realized by gluing, which can strengthen the fixed strength and firmness of the filter. The plane sealant of most products should be used in automation equipment. Besides the high demand of production such as bulb lamp gluing or product plane sealant, the links of the filter gluing should also be used, which should be set up by automation equipment. After setting the path parameters, the glue is evenly coated on the bonding surface with high precision. The uniform and stable amount of glue can enhance the fixed strength. The function of adding conical needle is to prevent scratch on the bonding surface of filter when gluing. It can be used to coat sealant, epoxy or solar sealant. The same kind of special conical needle is also needed to prevent scratch on the surface of material for bulb lamp gluing.

Polychromatic PP Conical Needle

There are similarities between filter gluing with dispensing machine and spherical bulb filling and plane sealing of semi-finished products. That is to say, the common points of surface treatment are as follows: cleaning the possible foreign dirt and dust attached to the surface, cleaning, roughening and activating the adhesive surface of the filter, controlling the flow of conical needle and strengthening the curing force and effect of the adhesive. Glue, and special solar bulb glue can be coated with solar sealant.

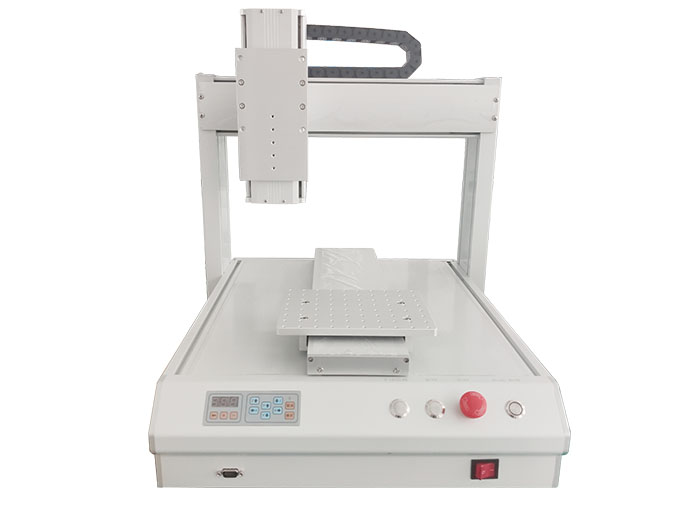

Medium-sized 331-stroke dispenser