The glue cleaning of dispensing machine needs to be carried out according to the steps and skills. If there is no skill and cleaning randomly, it will lead to unclean cleaning, which will affect the dispensing effect. According to the glue cleaning method of dispensing machine given by our company, residual glue can be thoroughly cleaned, and each step involves, which is very helpful for the life of dispensing equipment.

Glue cleaning steps of dispensing machine

Step 1: first, clean the glue inside the pressure barrel, use alcohol or organic solution to clean the inside of the pressure barrel.

Step 2: cover the pressure bucket again, transport alcohol and organic solution in according to the normal dispensing mode, and clean the first rubber tube and thimble dispensing valve.

Step 3: open the pressure bucket again, and then use clean water to clean it. Then remove the dispensing valve.

Step 4: according to the residual glue of dispensing valve, if there is no glue left, blow dry the inside of dispensing valve with blower. If there is glue left, dismantle the inside, wipe it clean and blow dry.

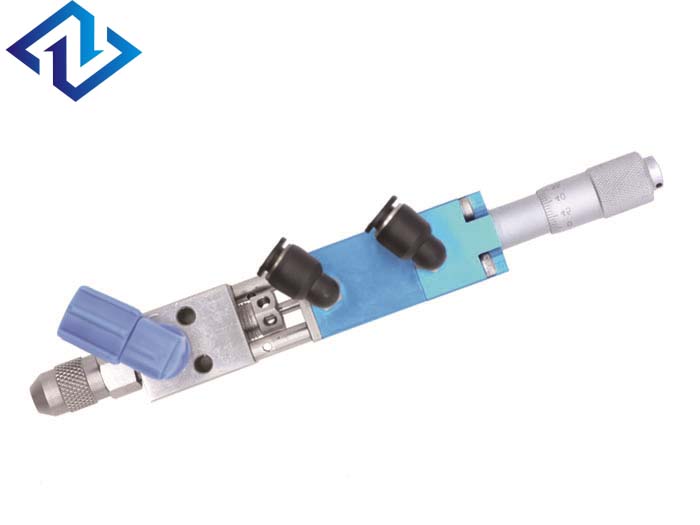

This is the overall glue cleaning method of dispensing machine. Micrometer thimble dispensing valve uses this method. In order to solve the problem of glue residue, it is necessary to use organic solution or alcohol to clean the residual glue. After dissolving, the nature of glue is changed, and the cleaning becomes simple.

Micrometer type thimble type dispensing valve is the same as other dispensing valves. Unless the glue is not dry, it does not need to be cleaned. Otherwise, the glue cleaning of dispensing machine needs to follow this step, otherwise it is difficult to avoid dispensing problems. The glue cleaning is very simple, mainly careful.