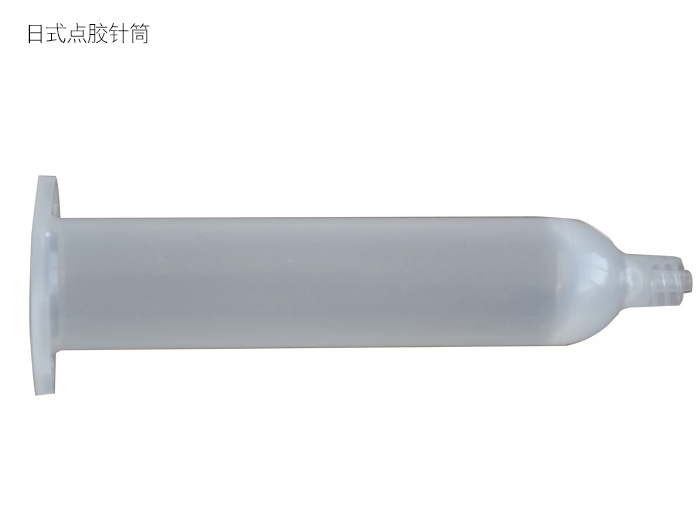

There are two kinds of problems affecting the bubble of dispensing syringe: first, the bubble of glue itself causes it; second, the air enters the interior of glue in the use process; two points need to be eliminated when using the Japanese dispensing syringe, so that the dispensing syringe can be used well; otherwise, the dispensing cannot meet the requirements, which is why the bubble has a great impact on dispensing.

Air bubble discharge method of dispensing syringe

To solve the problem of glue bubbles in the first point, some glues will have bubbles. For example, when epoxy resin glue is placed in the dispensing syringe, there will be bubbles, and the bubbles themselves will be inside the glue. Dispensing will cause the amount of glue due to bubbles, resulting in different water amount of each glue, resulting in poor dispensing quality. In order to achieve dispensing effect, bubbles need to be discharged and discharged The method can be centrifugal and vacuum pump, which can solve the existing bubble problem.

To solve the problem of glue bubbles in the second point of dispensing, we can use a tapered dispensing syringe or a large needle to solve the problem. Because in the dispensing process, there is air leakage in the dispensing syringe, resulting in air bubbles inside the glue, and the dispensing quality is relatively poor, the solution is very simple, the above is the solution, which is recommended by Shenzhen dispensing syringe manufacturers Type.

Shenzhen dispensing syringe manufacturers produce dispensing machine controller and Japanese dispensing syringe. Because they are consumables, they use a large amount of them, which is easy to cause air leakage when they are installed. If they use the corresponding dispensing accessories, they can directly solve the problem of dispensing bubbles, which is also convenient to use. In order to solve the problem of dispensing syringe bubbles, the controller of dispensing machine also makes actions, The air pressure can be sucked back into the dispensing syringe.