Among many dispensing problems, the non-uniformity of glue content is an important factor affecting the bonding or sealing. The quality of product glue bonding will be greatly reduced if the non-uniformity of glue concentration or proportion controlled by the two-component dispensing valve is as large as that of the ceramic dispensing valve. Therefore, the factors causing the non-uniformity of glue content need to be analyzed from many aspects. The following are the factors causing the non-uniformity of glue content. Some suggestions and treatment methods given by the manufacturer.

Application Treatment of Adhesive Glue

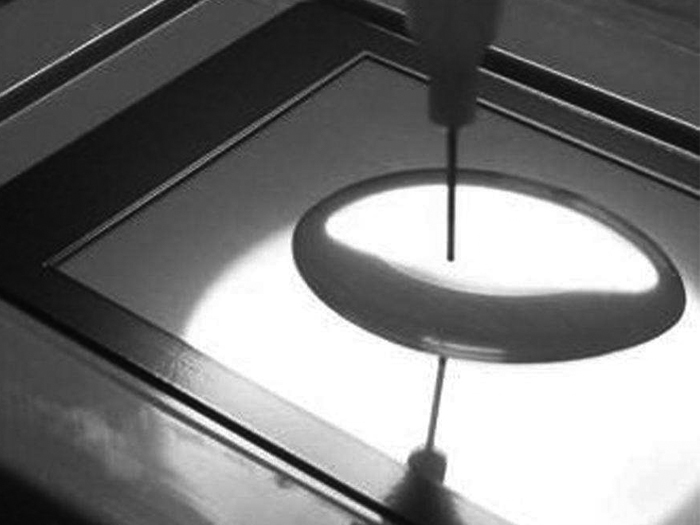

Micromotor gluing

Effect of related accessories on colloid

The needle at the bottom of the ceramic dispensing valve is also one of the factors affecting the glue content. It takes a long time to finish the motor gluing and to control the glue content of stainless steel. The dispensing needle may adhere to a part of the solidified glue. If this part of the solidified glue is not solved in time, it will adhere to this part, causing blockage, resulting in uneven glue output and affecting the glue production status, it can be straightened. Replacement or soaking with acetone solution to remove the curing adhesive is suitable for the production of batch motor coating line and stainless steel bonding on both sides. This is the potential factor that causes the uneven adhesive volume summarized by ceramic dispensing valve manufacturers for a long time.

To ensure the normal use of dispensing machine, besides guaranteeing the setting of parameters and paths, to prevent the quality of glue from causing uneven glue content and affecting the value of finished products.