It is very important to ensure the stability of dispensing by bonding and packaging. Satisfying the stability requirement is inseparable from the operator's operation. Correct operation mode can reduce the impact of possible problems. Of course, suitable application of accessories is also essential. Besides the need to ensure the correct operation, a small-sized ceramic dispensing valve is recommended to complete the accuracy control process. The application effect of high degree motor glue coating and uniformly distributed glue quantity gluing stainless steel is good. As a manufacturer of ceramic dispensing valves, neutral automation can provide various types of dispensing valves, which have a more prominent role in improving the stability of dispensing.

Improvement of Stability by Correct Operation

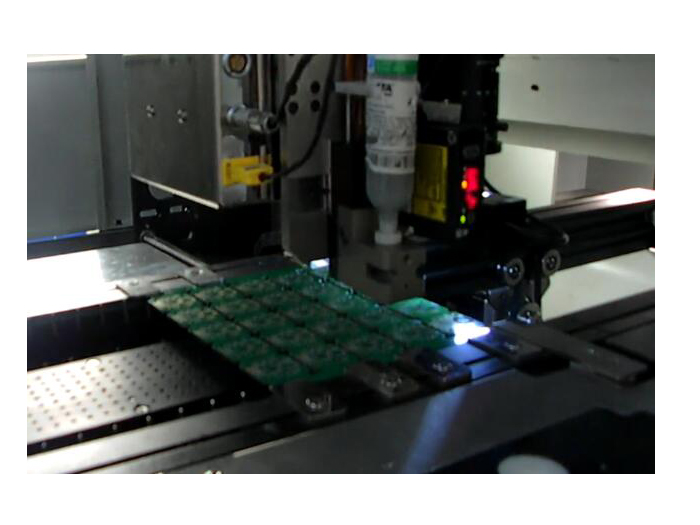

To ensure the stability of dispensing, operators need to do a good job of adjusting parameters and paths in the early stage, connect the control board of dispensing equipment to set the parameters and paths of dispensing, reset and start after pressing the operation, ensure that the stability requires correct adjustment of parameters and paths, and then check whether there are foreign bodies or lubrication degree in the guide rail and other parts, remove foreign bodies and add appropriate. Lubricating oil can improve the stability of dispensing machine moving dispensing. After adjustment, it can be used to finish motor gluing and stainless steel production. It has strong effect on guaranteeing the stability of dispensing in production. Selecting high quality ceramic dispensing valve manufacturers will give a brief description of the reasons for the large increase in dispensing stability.

331 stroke automatic dispensing machine

Reasons for recommending ceramic dispensing valves

Small ceramic dispensing valve

At present, different types of dispensing valves can be customized in batches, which can also greatly improve the stability and efficiency of dispensing in the production line.