Most products in LED lighting industry should be protected by glue seals. The main function of lamp seals is not only waterproof and dustproof, but also buffering. UV glue belongs to photosensitive curing adhesive. The curing rate will be improved after being irradiated by ultraviolet light. It is suitable for transparent lamp seals. The quality of UV glue stored in amber needle barrel is good. Among the same properties as plastering film and glass bonding, it is better to choose amber needle barrel for storage and control the bonding effect of UV glue.

Recommended UV glue for lamp sealing

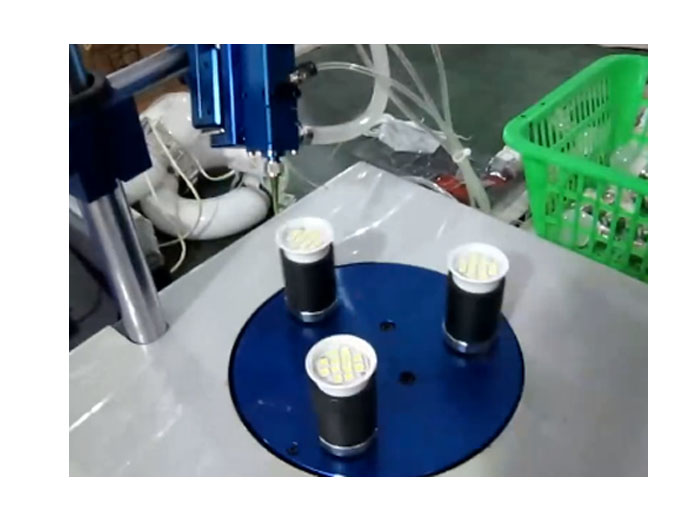

Sealed lamps and lanterns have good waterproof and dust-proof functions. The reason for recommending the use of UV glue is that the properties of sealing materials conform to each other. The special amber needle barrel is used to store UV glue and point it out. The connected needle barrel adapter is used to provide air-driven pneumatic flow and extrude glue. The needle barrel adapter with good integrity and sealability is suitable for guaranteeing the stability of needing continuous glue supply. The lamp sealing production line is used. After the lamp surface is treated, the amber needle barrel is controlled to apply UV glue to the uniform point of the sealing surface. Based on this principle, besides the sealing of the LED lamp, it can also be applied to the production of glass bonding and the application of the toughened film on the mobile phone.

Black translucent UV adhesive

The curing of UV glue needs to reach a certain degree in order to achieve its effect, so through appropriate ways, the air pressure through the glue driven by the dispensing syringe adapter is gradually cured by ultraviolet light. If it is irradiated by ultraviolet light for a long time without curing, the intensity of ultraviolet light can be adjusted to increase, or the fast reaction rate of photosensitizer can be selected to promote the curing efficiency, so that the UV glue dripped out of amber syringe can be fixed. The efficiency and quality have been strengthened, and the quality of lamp seals has been improved more significantly. At the same time, it has a good effect on other industries, such as plastering toughened film and two-sided glass bonding.

Sealed base for bulb lamps