In the manufacture of round bulb lamp, a round of built-in sealant filling should be carried out, which has the effect of waterproof, heat dissipation and protection. The corresponding fittings should be used to control the accuracy and flow rate of the bulb lamp filling, and the fixed-point glue control at the position of the quasi-glue filling should be used to glue the filling surface evenly. The tapered needle is recommended to be used as a pair. Uniform glue filling fittings inside bulb lamp can play a certain anti-scratch effect and control the flow rate of glue filling accurately. It can also be used in filter glue coating and other links to improve fixed-point glue control.

Selection of Conical Needle for Inside Sealing Filling of Bulb Lamp

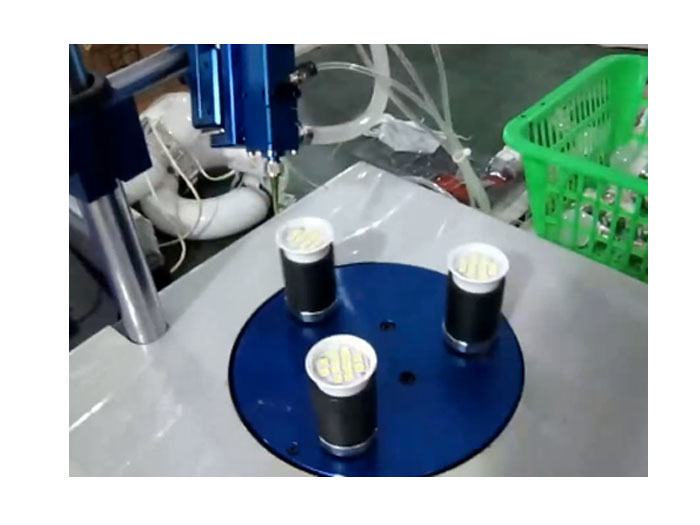

Ball bulb filling machine slot

Because the structure of bulb lamp is simple and needs some protective measures to improve its service life, epoxy resin and other resin glue are commonly used as protective measures. After glue filling, it has good waterproof and heat dissipation protection. It has strong resistance to dust and water in the air. It can be applied to bulb lamp glue filling and filter glue coating. For many production lines, in order to prevent the effect of fixed-point control glue filling on bulb lamp products, when assembling dispensing valves and tapered needles to control flow, the glue should be stirred evenly to avoid affecting the effect and quality of use.

Epoxy resin sealant

Special LED dispensing machine should be selected for batch glue filling of bulb lamp. Multiple round bulb lamp can be placed in multi-station circular groove for glue filling. Conical needle made of soft PP material is recommended for glue filling and scratch prevention of various products.