High precision product coating requires high operation and dispensing machine and other related requirements. At the same time, correct coating steps also need to be understood and implemented. This is the details often ignored when operating a sealed dispensing machine. Especially the quantitative control of the amount of glue in the process of electronic semiconductor coating has become one of the evaluation standards of accuracy and quality nowadays. How to align the sealant on the surface according to the steps is right. The test of operation, so this will briefly explain and explain the steps and operation of gluing.

Electronics Semiconductor Coating

Execution of Semiconductor Coating

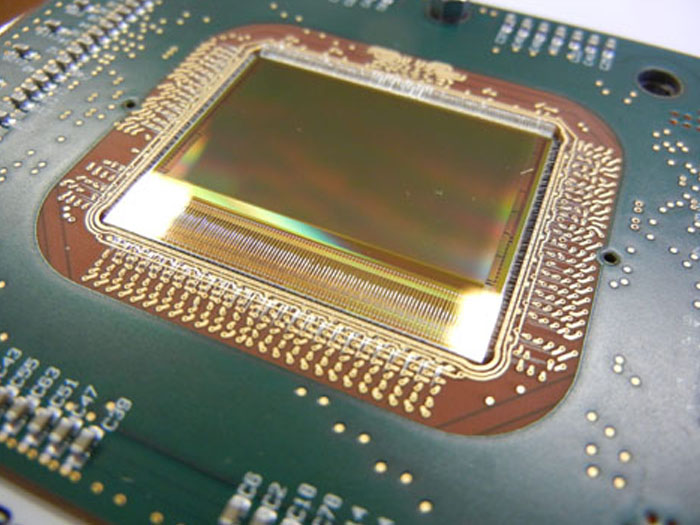

Semiconductor chip packaging

Implementing the correct glue-coating step has a great effect on improving the product yield. Because of the small semiconductor structure and high repetition precision of the demand, special-made glue valves are needed to be assembled on the sealing dispenser to enhance the accuracy and efficiency. Selecting screw dispenser valves for quantitative control has a positive effect on improving the quality of glue-coating. Electrically driven screw extrusion glue is used to produce glue, and the execution accuracy and quality are improved. Quantity stability is also strengthened, and the packaging control of sealant coating is relatively stable, so the selection of screw dispensing valve plays a decisive role in the batch strengthening of semiconductor coating.

Precision screw dispensing valve