The function of paint pressure barrel is to store glue and supply glue by pneumatic driving. The importance of replacing sealing rings from time to time can not be ignored. The sealing rings in rubber valves also need to be replaced regularly. The effect of sealing rings on product glue dispensing is strong but easy to be ignored by operators, which leads to the problem of uneven glue dispensing, especially the use of 502 points with high viscosity. The glue appears most frequently, which is not conducive to the production of precision and stability of electronic buzzer dispensing, so the importance of timely replacement of sealing rings can be emphasized.

The Function and Effect of Seal Ring

Batch buzzer dispensing production line needs to ensure good stability, mainly using 502 dispensing with medium and high viscosity. Because the amount of glue in the paint pressure barrel needs to be controlled by larger air pressure, the sealing ring is placed in it to prevent glue leakage and air leakage. The sealing ring inside the dispensing valve acts the same way, except that the sealing ring of the dispensing valve acts more effectively than the coating pressure. The sealing ring structure of drum is small, so the sealing ring will decrease after a period of consumption. It is necessary to change the sealing ring in time to avoid the impact. When the 502 point glue leaks out or leaks out, the problem of non-uniform glue coating will arise. In order to prevent the leakage glue from affecting the stability of electronic buzzer dispensing.

Stainless Steel Paint Sealed Pressure Barrel

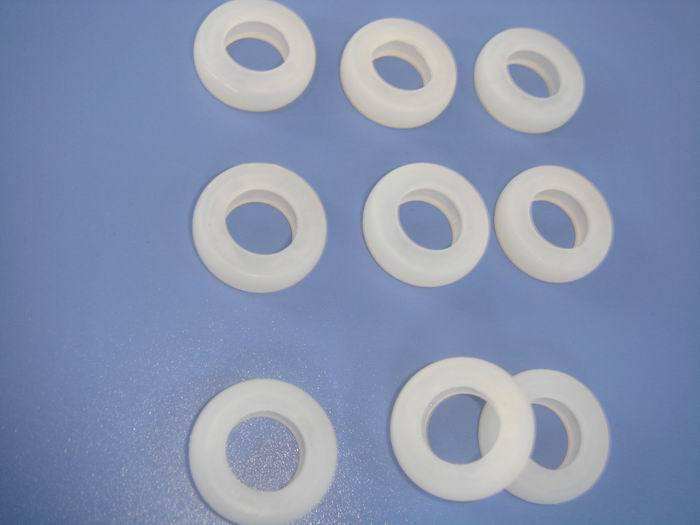

The sealing ring of coating pressure barrel is made of silica gel, which is wrapped in the back end of the barrel cover to cover the groove, so as to prevent the uneven coating of 502 glue points caused by leakage of air and glue, strengthen the stability and consistency of the buzzer dispensing, control the quantity of 502 glue points to produce glue is not easy to be affected by the lack of glue and other problems, the sealing ring made of silica gel has good durability, long service life and is not easy to wear, so the coating pressure barrel is not easy Replacement of sealing ring frequency is not high, can maintain several years of continuous use of leak-free glue to prevent uneven coating problems, and the rubber valve built-in sealing ring structure is thin and small, will gradually wear out after a period of time, so it is called consumables, the replacement frequency is relatively high, the uneven coating effect will be replaced.

2121 thimble dispensing valve