Non-uniformity of glue coating is a bad phenomenon in the process of dispensing. It is manifested in the lack of glue or excessive glue on the surface of the product. The problem of poor glue coating needs to be solved and avoided by electronic buzzer dispensing. Controlling the non-uniformity of glue coating at 502 points is related to the disposition of the coating pressure drum and the durability of the replacement ring inside the valve. Check and find out the reasons. Setting about the solution is the guiding direction. This time, we will deeply analyze the causes and solutions of the uneven coating.

Glue coating effect caused by fittings

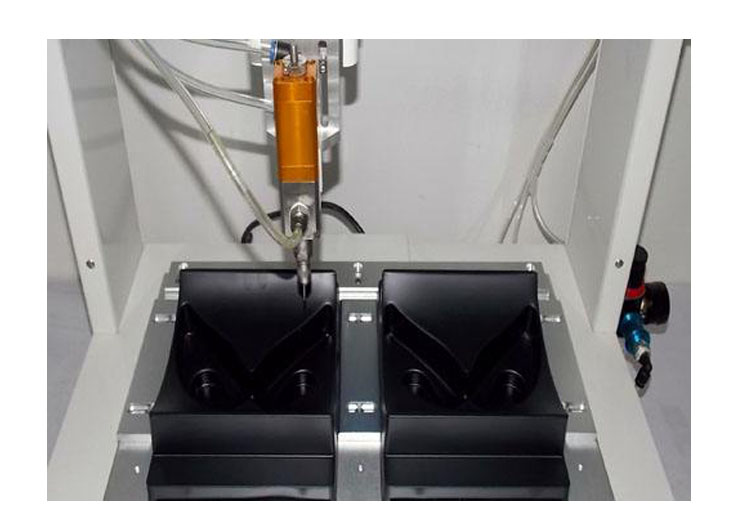

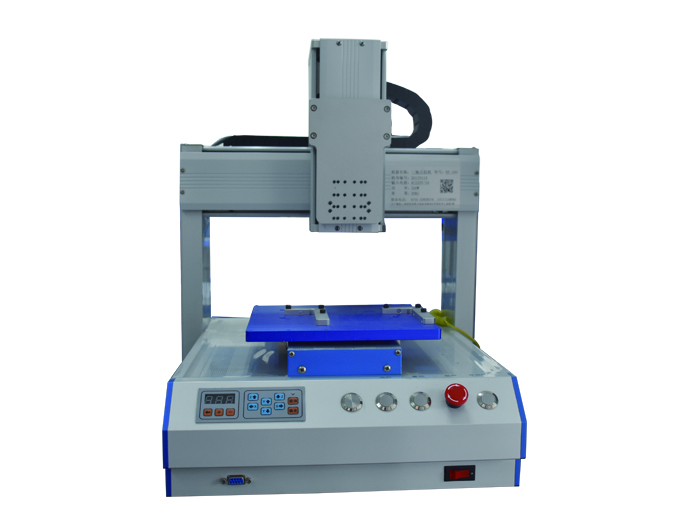

Various sizes of paint control valves and paint pressure barrels can be assembled when dispensing with dispensing equipment. Pressure barrels are mainly used to store large volumes of rubber and convey glue through pneumatic drive. They can store and transport medium and high viscosity fluids to provide dispensing. The problem of non-uniform dispensing may be related to the internal conveying pressure. Middle and low viscosity fluids use top dispensing to produce high viscosity glue. Water through the bottom of the gum, the need for high pressure delivery, when the pressure of the paint barrel is insufficient to drive the glue is poor, so the part used for gum coating often appears the problem of lack of gum or less gum sometimes more gum, which directly affects the application effect of commonly used glue products such as 502 gum, and most of the impact on the dispensing of buzzer is therefore uneven, of course, as well as Check and replace the built-in parts of rubber valves such as sealing rings.

The sealing ring in the rubber valve is used to prevent the leakage of glue in the rubber valve. Some glue will leak out during the 502-point glue conveying process. The function of the sealing ring is to prevent the leakage of glue. The unstable glue conveying causes the problems of uneven glue coating and lack of glue. It is often checked that replacing the sealing ring can prevent the leakage of glue and lead to the uneven glue coating of the product.

Demand for dispensing buzzer

Because the structure of electronic buzzer is generally small and delicate, it is necessary to control the amount of 502-point glue coating within a certain range and use high-precision filling technology to ensure that the yield of good products reaches the standard. Through the inspection procedures and the performance of fittings to replace the sealing ring and other stability, to ensure that the batch production of buzzer dispensing meets the requirements and prevent the impact of uneven glue coating.