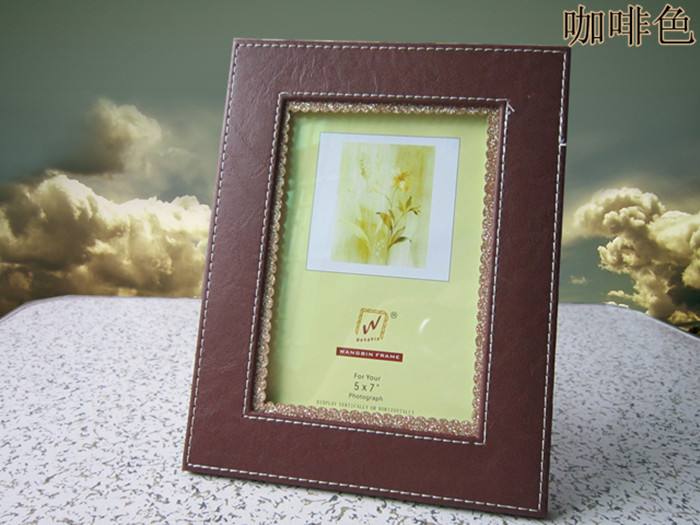

Some special production lines need to drip UV glue for solidification or packaging, such as batch photo frame dripping glue will be used, because most of the photo frames are made of glass, with transparent properties can be dripped with UV glue, UV glue is also called ultraviolet glue, through ultraviolet light irradiation will accelerate the solidification rate, need to use special dripping syringe to prevent the storage of UV glue solidification clogging, according to this. One characteristic is mainly used for bonding and packaging of transparent materials. This lecture is about the problems and effects of dropping UV glue, which is a kind of ultraviolet glue.

Problems and Solutions of Solidification in Use

Ultraviolet glue is also called ultraviolet glue in the industry. When exposed to ultraviolet light in the light, it will accelerate the reaction rate curing. So when storing UV glue, the container with color should be selected to weaken ultraviolet light. It needs the transparency of the adhesive surface to strengthen the curing rate of UV glue dropping. When dropping, the needle and syringe with amber color should be used to align the glue to avoid curing clogging during dispensing. The impact of the problem, especially the batch production line of photo frame dripping glue to prevent this problem.

Special tape coloured rubber cylinder

In practical application, attention should be paid to the problem of light coherence when the effect is good. Taking the photo frame dripping UV glue as an example, most of the photo frames are made of glass with good light transmittance, which takes a long time. The colloid in the dripping syringe can not be strengthened by light. The installation of ultraviolet lamp can provide a long time of light enhancement, which can enhance the curing rate of the UV glue and improve the ultraviolet glue at the same time. The application value and effect are the guarantee of guaranteeing the dropping efficiency and quality rate of photo frames.

Ultraviolet glue has a wide range of applications, mainly in the fields of electronics, electrical appliances and optics. When dropping UV glue, attention should be paid to the impact of the problem and the use of the situation, so as to solve the problem as soon as possible in order to produce more stable.