Some specific products need to be filled with liquid hot-melt adhesive, such as shoes, textiles, books and periodicals, etc. Hot-melt adhesive dispensing is needed. If hot-melt adhesive is used to fill the ordinary valve, it is not applicable. It is necessary to use a specific hot-melt adhesive dispensing valve to apply. Of course, not only that, but also many details and choices need to be paid attention to when using hot-melt adhesive dispensing.

Colloidal properties and usage

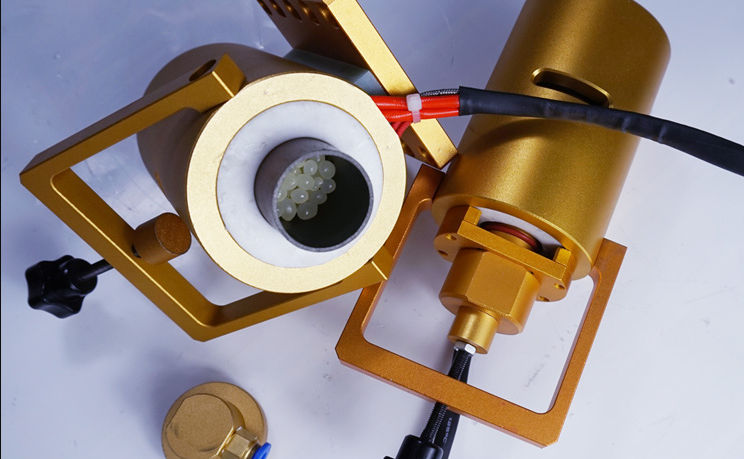

Single-station hot melt dispenser

Characteristics of special dispensing valve

Because of the unique characteristics and operation requirements of hot melt adhesive, special hot melt adhesive dispensing valve should be used to control dispensing. Copper shell can withstand the flow of higher temperature fluid and control the glue evenly. Temperature sensor is used to control the temperature of the fluid, which solves the difficulty of temperature control inaccuracy and improves the effect of melting application of hot melt adhesive. Copper valves are always used in dispensing machines to store and supply glue.

Users need to pay attention when using hot-melt adhesive dispensing. The components with high melted colloid temperature can not be applied. To ensure normal use, the storage capacity should be kept at about 4/5 of the total capacity.