The use of dispensing machine has been widespread in the production of uniform glue coating industry. The automatic dispensing equipment has the characteristics of uniform glue coating and labor saving. This time, we say that the effect of uniform glue dispensing is closely related to the dispensing needle and the dispensing needle nozzle. The main reason is that the burden caused by frequent use of needle causes problems. Therefore, it is important to analyze and adjust the needle in many aspects.

Effect of wear of dispensing needle

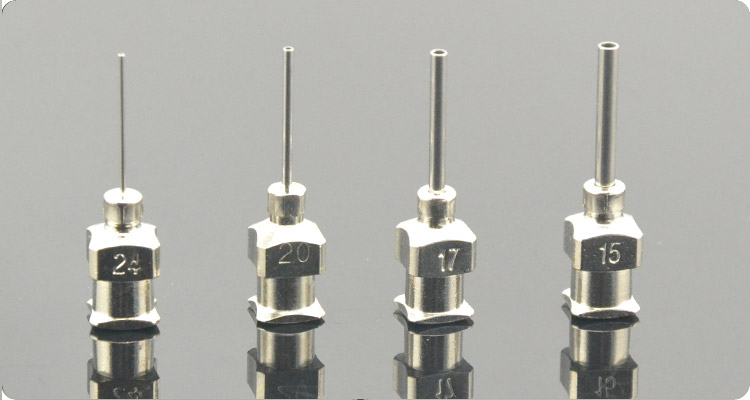

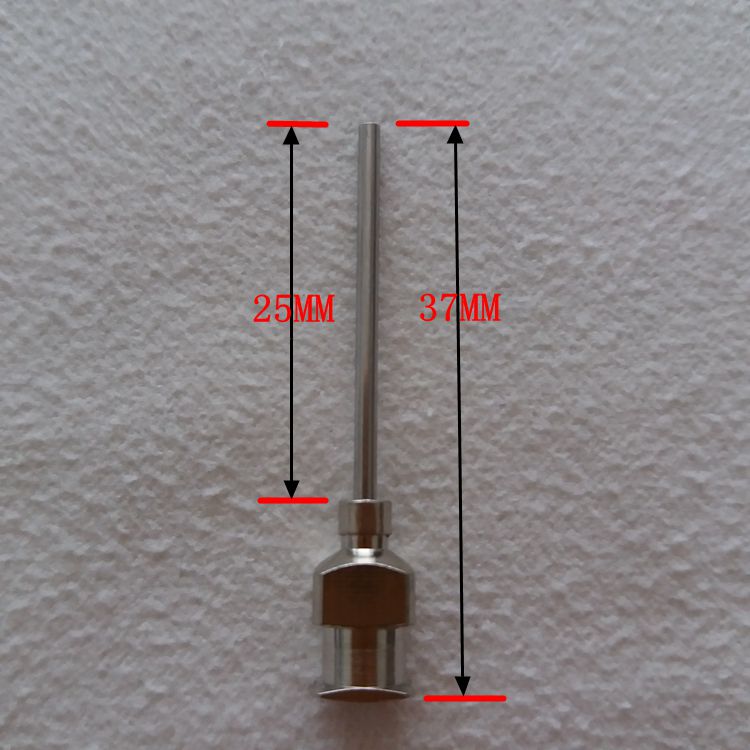

High-precision dispensing needle is the most commonly used needle in dispensing machine. It has the advantages of long life expenditure and uniform glue coating. It is an important accessory for selecting dispensing machine. When it is found that the direction of glue coating is not correct and the uniform precision is affected, timely attention should be paid to it. It is difficult for most operators to associate it with consumable needle. If the needle is not selected according to the glue quality, it may lead to partial curing. The uneven dispensing of glue, high precision dispensing needle uniform coating quality is affected by this, and the bottom dispensing needle nozzle for a long time will also be part of the friction and wear, in the long run will affect the accuracy and quality of glue coating, so it is very important to regularly check whether the material of high precision dispensing needle is affected by wear uniform coating quality.

Adjustment for rubber tapping needle

If the effect of uniform glue coating is found to be affected, it is necessary to check from the air pressure source, the glue valve and even the dispensing needle. If the dispensing needle wears out for a long time, it must be replaced, including some special dispensing needle nozzles. The external impact of the needle nozzle is the same, and the replacement of new high-precision dispensing needle can ensure the quality of uniform glue coating in the production line. Efficiency.