Is having a profound impact on the development process of dispensing machine in manufacturing industry, bonding, packaging, filling products in the production process will need to be applied to the dispensing machine to complete the effect of high precision dispensing needle on the industry is very large, the quality and effect can enhance the product production, different production needs to be applied to different dispensing needle and for production use.

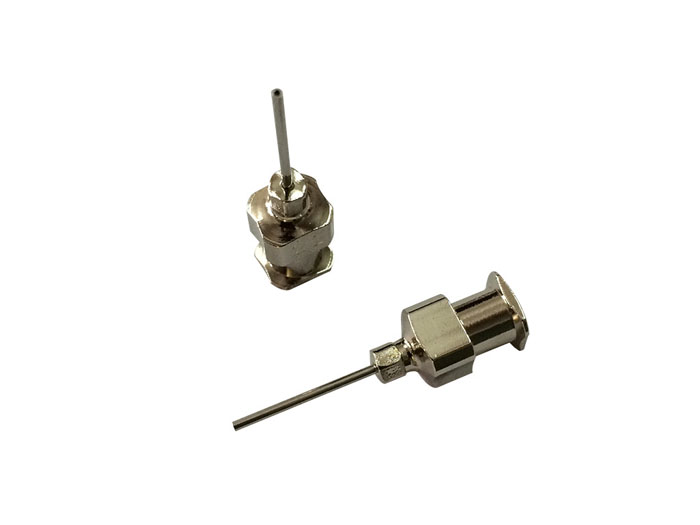

Metal needles are commonly used in the production of accessories industry, have the characteristics of long service life and durability, suitable for high demand for dispensing the production work, can withstand a certain corrosive glue, metal needles suitable for high viscosity and low viscosity glue glue for dispensing, metal material can ensure stable and efficient execution of dispensing work without damage, long-term use will not affect the normal dispensing accuracy and dispensing quality, provide more value for users of the industry production effectively.

Some products need dispensing link to ensure a high quality stable and uniform dispensing, dispensing needles on the alignment control effect is always unsatisfactory dispensing, dispensing error caused by the greatly reduced the value of the finished product, glue dispensing needle point accuracy using high precision can effectively improve the products, using high precision dispensing needles to avoid clogging and glue drawing etc. common problems, improve the fluency and quality of dispensing process, suitable for electronic industry and other small parts production, manufacturing industry production process more stable and efficient dispensing.

For some parts of the Seiko part, we need to avoid scratching the product surface in the high-speed dispensing link. We can use soft PP flexible dispensing needles or brush dispensing needles to fulfill the needs of the industry.