With the expanding application of dispensing, dispensing for use in the wider production, some special products of the production work needs to be applied to different dispensing needles, if the need for irregular seam filling, you can use the curved needle for dispensing dispensing, dispensing needles bend so what is the impact on the dispensing quality?

The electronic parts of the industry production of dispensing needle specific demand is higher, in addition to meet the coating effect of the integrity of products, but also need high speed dispensing needle smoothly out of glue, if it is very difficult for the ordinary dispensing needle dispensing of irregular electronic parts, through the use of dispensing needle bending can be filled for irregular electronic components the design process, bending angle in order to effectively align irregular slits for dispensing, dispensing accuracy and will not affect the dispensing quality, with higher work advantages than straight needles, suitable for many kinds of glue to glue water, avoid glue resistance affected by glue fluency and coherence in bending.

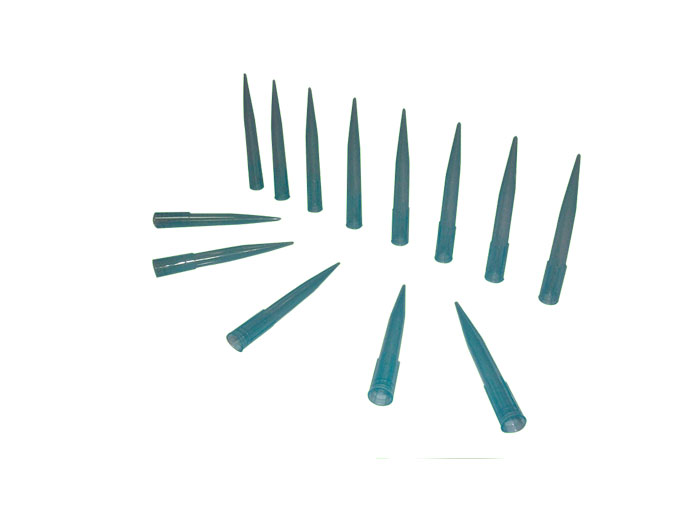

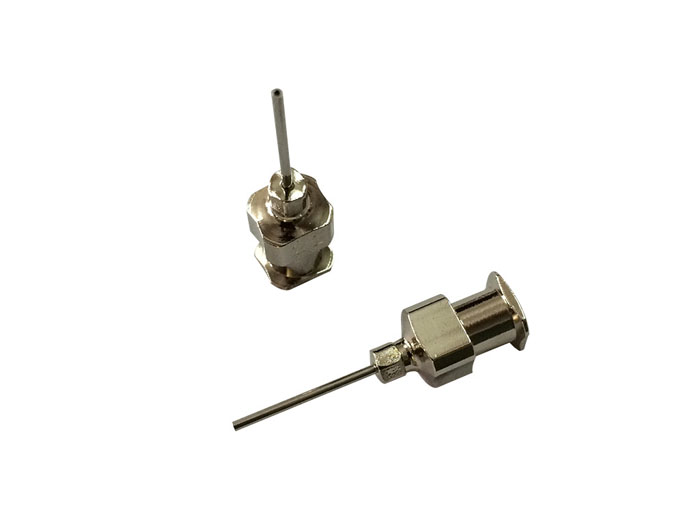

According to the demand of the actual work can be bent dispensing needle making a variety of angles, such as 30 degrees 45 degrees 60 degrees 90 degrees, made of stainless steel with excellent corrosion erosion ability, users choose high precision fine needles with glue effect of high precision, can meet the requirements of more comprehensive industry, and support a variety of dispensing valve the dispensing needle supporting work.

The dispensing needle bending is mainly used for irregular seam of glue filling, dispensing more visual effects to help users improve product quality and adhesive bonding strength, bending structure of high precision dispensing needles and small quantity of cement fine application plays an important role in the production of electronic products in the work, so the bending effect of small needle dispensing.