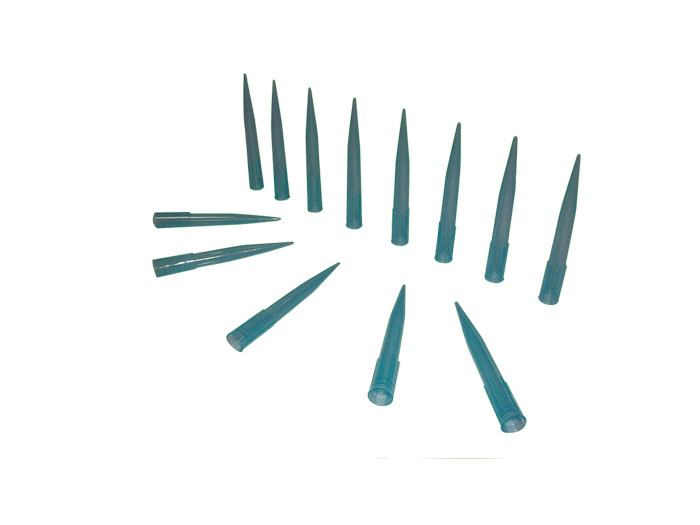

The tip of the pinhead is curved, so it is called the pinhead, one of the types of the needles. The dispensing needle bending precision bending process produced, not because the bending effect of dispensing smooth, suitable for use in special industries such as electronics industry, automotive parts, medical instruments, these industries for the dispensing glue volume requirements are different, so the use of glue can control point bending needle dispensing accuracy?

Because the tip of the pinhead is curved, it is different from that of the other needles. The needle dispensing accuracy of the needle and the glue glue on the amount, if the volume of the plastic bending dispensing needle size is not suitable for the product requirement, will affect the glue dispensing needle point bending accuracy, so in the selection of the best according to the curved needle dispensing dispensing requires the selection of diameter, bending angle for the point plastic bending needle, avoid the point out of the dispensing glue dispensing accuracy inappropriate influence.

From the above, it can be seen that the amount of glue produced by the needles with different sizes and angle angles is different. As mentioned above, not because of the needle bending bending needle dispensing dispensing effect smoothly, so rarely glue plug phenomenon, but in use because of some causes of solidifying glue phenomenon in the needle, will not only affect the dispensing glue volume is not uniform, but also caused some impact on the glue point. Then when the dispensing needle bending block?

General dispensing curved needle head is made of plastic material and stainless steel, when dispensing curved needle head made of plastic glue solidification phenomenon appeared to replace the use of can, if using stainless steel needle dispensing glue in the bending appear solidification phenomenon can be used when the heater will melt glue, the glue dispensing work, ensure the accuracy.