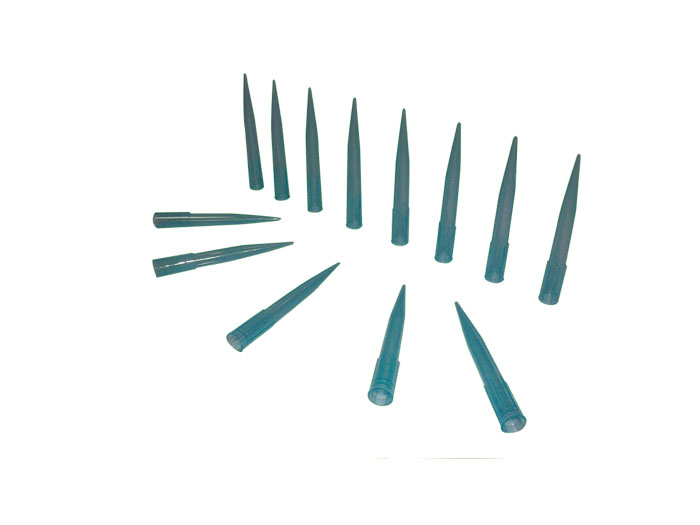

Mixed plastic dispensing needle belongs to a special parts, dispensing needles of other types are afraid of blockage, and did not dare to put things in the needle, mixed plastic needle is to come, the RM spiral blade mounted on the inside, can effectively improve the dispensing effect, but there are also some problems need to pay special attention to. Improper operation not only can improve the effect of dispensing, dispensing needles will be damaged.

Mixed plastic dispensing needle which has some problems, although adding anticorrosive materials in plastic, but the storage time is too long the glue will have some corrosion, this is a noteworthy problem, mixed plastic dispensing needle instead of disposable items, can also clean the glue used again by glue corrosion waste valve a dispensing needle.

The dispensing needle is divided into static and dynamic, static mixed plastic dispensing needle then you need to pay attention to the flow of glue, long time no glue, glue will solidify in the hose, plastic mixture dispensing valve using dynamic, will not have these problems, consistent with the use of static dispensing needle flow fast AB glue each, dispensing needles have some advantages, otherwise will be other products to replace.

The dynamic needs of mixed plastic dispensing needle to pay attention to the problem, because the dynamic needs in accordance with the motor and valve, through the movement of the motor can rotate the rotating spiral blade, will drive the mobile dispensing needle machine, it also has a bad place for dispensing, unless the motor vibration all need to eliminate, use each dispensing the needle is bound to have problems, these problems will lead to decrease the effect of dispensing, in the operation process of all these problems need to exclude the effect of dispensing, also improved.