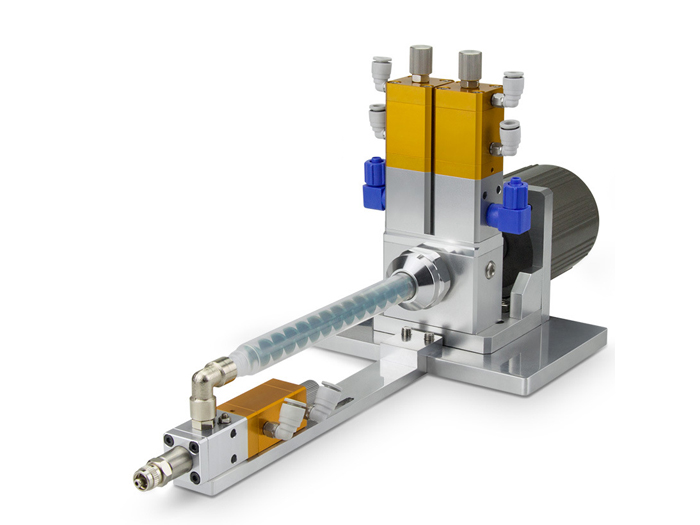

There are many types of double liquid dispensing valves produced by our company. In the last issue, a representative static double liquid valve has been introduced. Today, we will introduce the characteristics and functions of dynamic double liquid dispensing valve. Our company is a manufacturer of dispensing accessories, with a large number of different characteristics of the valve, just take a few representative dispensing valves as today's publicity, let's get to know.

Features of dynamic double liquid dispensing valve:

1. High viscosity glue mix, glue viscosity more than 20000, or even higher.

2. The glue is easy to mix. The motor is used to mix the glue. The mixing tube is only an auxiliary function.

3. The glue is strong and can be reversed to realize the glue back absorption function.

4. It has precise motor controller, which can adjust the speed according to the proportion and viscosity of glue.

5. The mixing ratio of glue can reach 5:1 or below, which is higher than the mixing viscosity of static double liquid dispensing valve.

6. With control device, it can accurately control the glue output.

Parameters of dynamic double liquid dispensing valve

Model: zz-dtx-60 working air pressure: 0.4 ~ 0.8MPa

Glue valve cylinder: double acting cylinder; glue mixing ratio: 1:1 ~ 5:1

Glue adjustment method: precise nut adjustment product combination: double liquid valve + motor + governor

Working feed pressure: < 10kg minimum: 0.1

Main material: stainless steel + aluminum alloy; feed port size: 1 / 4N "NPT (f)

Glue viscosity: 20000 viscosity starting weight: 500g

Use glue: epoxy resin glue, two-component glue, silica gel, styrofoam, crystal glue, etc

Application Industry:

Power supply glue, relay module glue, epoxy glue, two-component glue, automobile generator glue, ignition coil glue, solar electromagnetic board glue, LED lamp glue, shoe glue, sensor, PCB board, sensor glue, etc.

To use the two-component dispensing valve, it is necessary to have its own rules, and understand how much viscosity and glue mixing ratio are required. Otherwise, it is impossible to achieve the two-component glue filling. The glue also has its own characteristics. These are clear provisions. If the manufacturer needs dynamic two-component dispensing valve, it is better to follow the manufacturer's requirements, and the effect will be better than the automatic exploration.