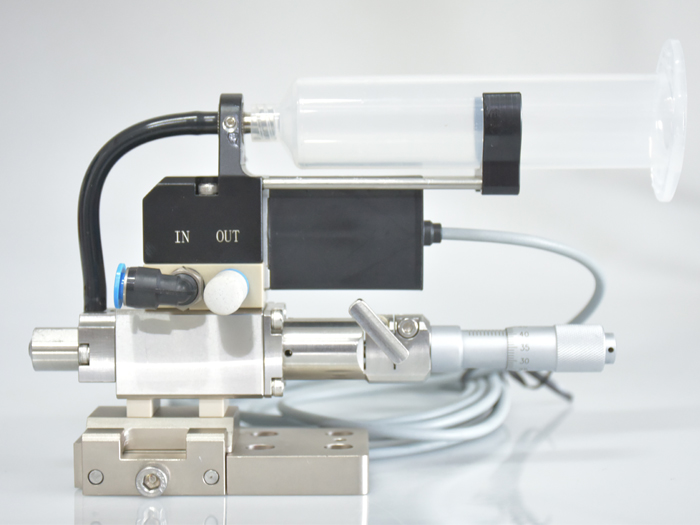

The standard pneumatic control clamping pipe dispensing valve uses plastic hose as the dispensing valve structure. When the dispensing valve is closed, the plastic piston rod will clamp and close the plastic pipe. When the "valve access" command data signal opens the valve, the piston rod will retreat under the effect of standard air cylinder, so as to achieve better rubber control effect and meet the production demand.

Working principle of dispensing valve of clamping tube

When the "pneumatic valve is closed", the hose is clamped and closed by the plastic piston rod. When the "pneumatic valve is open" command indicates that it is open, the piston rod retreats under the effect of the pneumatic cylinder. After the hose is opened, the colloidal solution flows into the dispensing valve. The total flow of the colloidal solution can be controlled according to the regulating screw which limits the movement of the piston.

The use of clamping tube can better control the glue flow, in fact, it is more consistent with the diverse use, some products need a large amount of glue, some need a small amount of glue, the use of clamping device can well control the glue flow, which is of great help for dispensing.

Automatic dispensing platform

Characteristic

2. Raw materials can be supplied according to the material barrel and injection barrel (that is to say, these devices can be used to store glue)

3. Fast cleaning speed, glue capacity cleaning, especially convenient

4. When the working pressure and time are allowed to glue, the clamping device of glue valve can be adjusted at will.

5. For example, add dispensing syringe, which can increase glue storage.