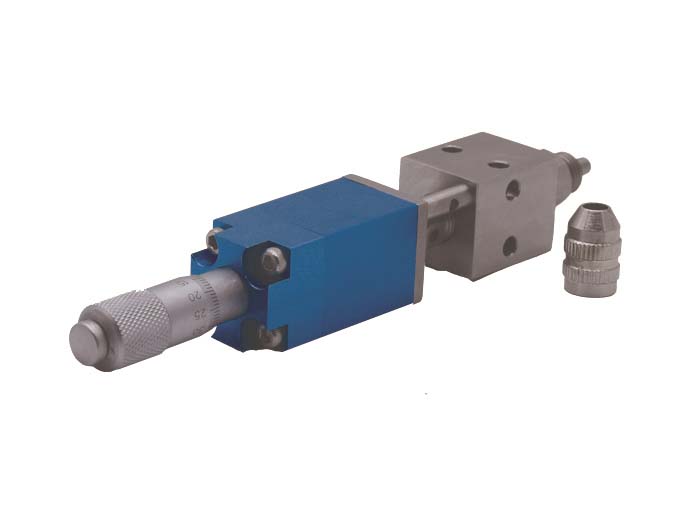

Valve is an important part of dispensing equipment. The function of valve in dispensing machine is to control the amount of glue and glue. It acts as a "goalkeeper" and needs to select various types of valves according to the needs of users. The valve is famous for its unique collision needle drive glue, and the effect of collision needle control glue volume is faster and more complete.

Controlling glue with collision needle

The pin-impact rubber valve controls the piston in the air pressure extrusion hose, fills the piston with glue, and then enhances the pressure to drive the glue extrusion. The glue will be dispensed by the impact of the piston, and the door can also be pulled back and sucked back. The advantage of the execution mode of the pin-type rubber valve is to reduce problems such as tension and leakage.

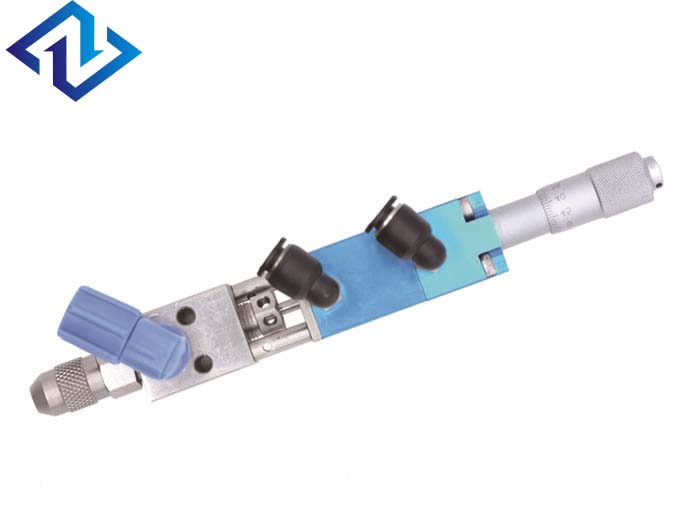

The use of pin-impact rubber valves has different effects. When using the pre-actuator, the valve can control the amount of glue to complete product dispensing. When pulling back and reversing, some glue can be sucked back to reduce the problem of glue overflow. The internal components of the valve are tightly connected, and the sealing is good. The front and back suction functions are more perfect. It is easier to suck back the control glue, which is beneficial to the dispensing effect products of the valve.

Attention and maintenance knowledge when using impact needle rubber valves, there are some problems need attention. The common problem is the effect of back pressure on pullback. If the operation is inaccurate, the glue will leak. Large dispensing needles need to be replaced.

Needle valves also need regular maintenance and cleaning. In the dispensing process, some glue remains in the valve. Most glue is partially corrosive, so some parts of the pin-impact valve are vulnerable to glue erosion. If it is not cleaned in time, the service life of the pin-type rubber valve will be shortened. If necessary, it should be cleaned and maintained after daily use.

In order to improve the stability and efficiency of rubber volume control, the pin-impact rubber valve should become a tool for users to control the rubber volume stably.